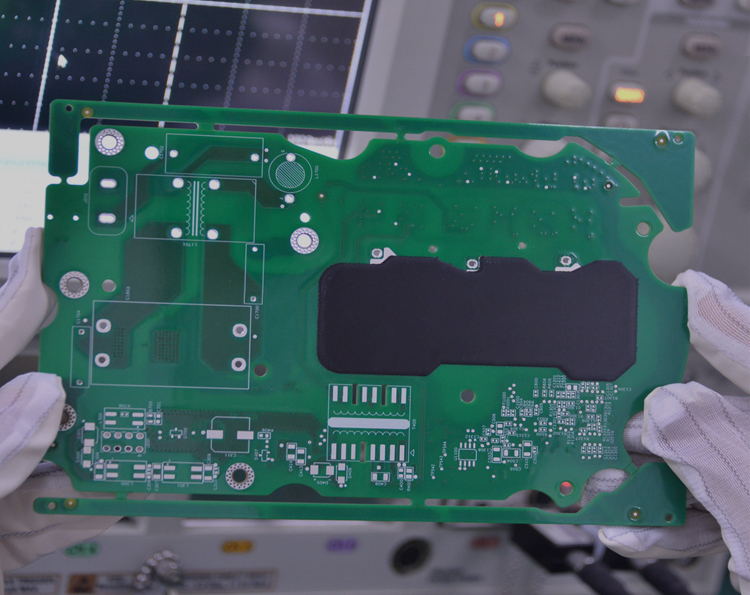

Craft show

| Layers | 6L |

| Board thickness | 1.6±0.16mm |

| Material | SL S1000-2M |

| Line width / space | 0.18/0.16mm |

| Minimum aperture | 0.3mm |

| Surface treatment | OSP |

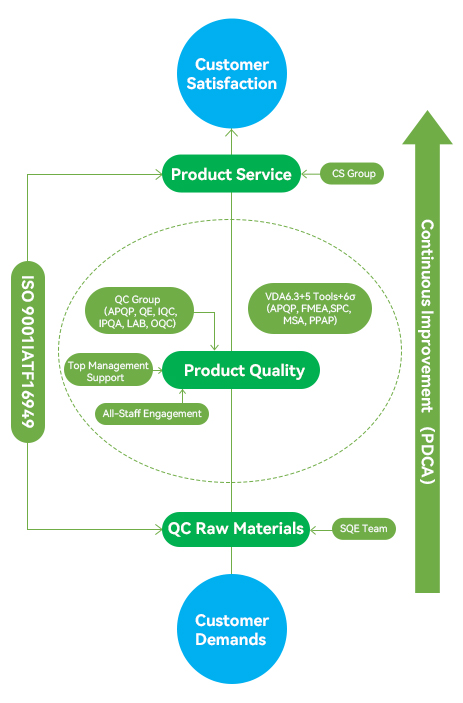

Suntak Technology obtained the IATF16949 certificate for the first time in 2005, and reached the strict quality requirements for automobile products. To become the world’s top automotive PCB supplier, Suntak Technology has invested a large amount of manpower and materials into the R&D and production of automotive PCB, and implemented strict controls on the production process, quality and traceability, to guarantee the quality for customers. Our PCB products (thick copper, HDI, high frequency and high speed, etc.) have been extensively applied in the electronic driving system, central control system, vehicle electronics, and communication entertainment system, and can also simultaneously meet the technical development requirements for longer service life, higher temperature load, and smaller design distance.

Zhuhai No. 1 Plant, as the Group’s most automated modern high-tech plant, is committed to making products that are mainly applied in automobiles, computers, photoelectricity, security and other fields.

We use raw materials from world famous brands, have established incoming material inspection regulations that comply with international and customer standards, constantly trace and promote supplier quality improvement activities, and build and maintain strong cooperation with suppliers.

We firmly believe that high-quality products are produced instead of tested. We have standard manufacturing processes and detailed production line operation manuals, to guarantee correct implementation of operation regulations and standards.

We strictly inspect and control the quality of all outgoing products according to international and customer standards. Moreover, we follow the quality performance of products after delivery, and adopt rapid and effective improvements to resolve any problems of abnormal quality raised by customer.

Professional service team, the first time to provide customers with product consultation, technical solutions, on-site technical support, to solve customer products in the application of technical problems, to meet customer needs, our vision is to exceed customer expectations, create higher value.

Responsible for managing the supplier and incoming materials

Responsible for promoting all systems of the company as well as the maintenance and the import of new customers

Responsible for the first article inspection of the process, the patrol inspection, and taking the lead in improving process abnormality and managing defective products

Responsible for monitoring the solution in the production line and the reliability of products

Responsible for the inspection before delivery

Responsible for after-sales service

Zhuhai F1 mainly produces multi-layer circuit boards, which are used in automobile, computer, security, optoelectronics and other fields

more

Become a world-leading manufacturer of Circuit board

Follow us

© 2023 Suntak Technology Co., Ltd.